How Provolone Valpadana DOP is made

Home » Elaboration of Provolone Valpadana DOP cheese

The phases of the production of Provolone Valpadana DOP, between tradition and technology

Production technique

The technology of transformation of the cheese intended for the production of queso Provolone Valpadana DOP is the classic processing of the “thick pasta”, based on physical, chemical and bacterial criteria, and is developed in some essential phases:

The stages of processing

1

Preparation of the beer in the caldera

The vacuum cleaner, naturally acidified and selected in compliance with the provisions foreseen by the legislation, in terms of geographical procedure and feeding of the vacuum cleaners, recognized before 60 hours following the first order, can be treated thermally until the pasteurization temperature in case it is intended to be produced Provolone Valpadana DOP Sweet yes there Spicy type weighs 6 kg; However, for the Picante type of more than 6 kg, the food can be, as maximum, termised.

2

Addition of milk ferments and cuajo cultivars

The culture of lactic ferments used in the production is constituted by natural injected sugar, so to speak, by the microbial culture naturally selected in this specific production of products in the residual sugar from the production of products from the previous day. It is evident that the wrapped pork is one of the pillars of this evening's transformation Provolone Valpadana DOP, so that the adequate battery charge will be needed to create the conditions until the other phases proceed in an optimal manner.

Before discussing the coagulation of the milk, it is important to discuss the meat and its typologies, which then characterize the product. What is the enzymatic complex that modifies the casein of the milk causing the coagulation of the same milk. The methods used in the cheese industry today are different, but for the production of this Provolone Valpadana DOP two types are authorised:

- the ternero cuajo in liquid form (ternero abomasum extract), which essentially contains two enzymes (quimosin and pepsin);

- the rope and/or cabrito mixture in the form of pasta (cordo and/or cabrito abomas, picados and amasados with salt) which contains various enzymes, such as quimosin, pepsin, lipase and the whole zymase (enteral enzyme group) of the fourth largest area of sheep and goats, today I only know it partially

3

Coagulation

Conceptually, the coagulation of the milk (in the production of Provolone Valpadana DOP produces at a temperature of 36-39 °C), is the change from the physical state of the milk (from the liquid to gel state), obtained thanks to the action of the cuajo over the casein dispersed in the milk.

In practice, the casein mixtures, instead of “floating” in the milk, after the action of the cooking mixture are united forming a three-dimensional network that encompasses the fat, a part of the pork and the lactic ferments, thus forming a jelly ( bicarbonate paracaseinate) commonly called cuajada.

Ultimately, the liquid mixture of ternero will give rise to a suitable mixture for the production of Provolone Valpadana DOP Sweet, while the quantity of pasta made of string and/or cabrito will give rise to a mixture suitable for the production of Provolone Valpadana DOP Spicy, That is, the lips, combined with the complex enzymatic system present, will favor the appearance of the complex aromas which, combined with the trigeminal sensations, characterize the uniqueness and precision of this product.

4

Fermentation and cooking of the dough

After processing the leche in the boiler, the mixture is left to rest on suitable surfaces, so that it can ferment and acidify at the right point and the ideal conditions for the dough are created. This fermentation is no longer the continuation of the process begun with the addition of the injected pork to the leche and, above all, the correct microbial development during the phases of elaboration and maturation of the dough, however, this phase is controlled with appropriate teams. In the past, to make sure the pasta was on the list to be rolled, proceed with intent, submerging a piece of pasta in water and stirring, to check if it was pulled correctly, otherwise you should wait another time and then turn to try it. In this practice, the name "prova" (prueba), "provatura" (probar), provola and, finally, provolone. Once the point of correct maturation has been reached, the dough is short and chilled to retain the fermentation and, subsequently, it becomes chilled.

5

Hilarious

This technological practice goes back to the name of wool kneading, in the sense that the dough of the wool hardens when it is hot and, by pulling it, it is pulled to form very large wools.

If you think that only 10 grams of dough, if you wish, you can spread it by up to one metre.

There hilarious if it is produced in water at a high temperature and, during the past few years, it has abandoned the function of pasteurization “before its time”, it is said, before the founder of modern microbiology, the professor. Louis Pasteur (1822-1895), hiciera sus descubrimientos.

Practically the structure of the grainy and discontinuous pasta is converted into fibrous, continuous and plastic. Nowadays the process of grinding can be carried out, artisanally by hand or, more commonly, using continuous grinders which can ensure a respectful process of the loyal and constant uses transmitted by tradition.

6

Molded, cooled and solidified

After baking, the mass of the cheese, still hot, is shaped manually or using suitable special molds, in the shapes and in the programmed dishes which, then, are placed in current cold water to favor rapid cooling and consequent solidification.

7

Salazon

Once the cooling and solidification are finished, the cheeses move on to the salting phase, where they remain for a few hours until three days, according to their shape and weight.

During salting, the process of osmosis (interchange between mixed liquids) occurs which favors the entry of salt and the salt of the bean.

Once the salazón is finished, the cheeses are dried and prepared to enter the curative containers.

8

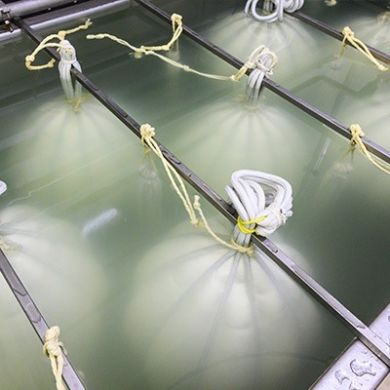

Atadura

The preparation phase for the cure consists of practicing with appropriate precautions for contact with food, following a technique that is as traditional as it is practical and efficient. The type of attachment with the "mothers' arms" constitutes the extra touch of the quesero. Indeed, it is always related to the shape and weight that the steps of the suction legs are expected.

The forms, conveniently dried and possibly humidified, are treated on the surface according to the indications of the current legislation, in order to preserve the quality of the attacks of mohos and mites. Before entering the almacén, for the expected maturation period, if you place the escarapela, the brand which identifies the only PDO product. At the end of the treatment, the labels and the paraffin will be applied to the forms to be sent for distribution.

9

Care

Precisely in the Almacenes, thanks to the physical, chemical and microbiological processes of the careLet's look at the shapes in their fascinating completeness, noting only that it is precisely the treatment that releases all the natural sensorial potential of Provolone Valpadana DOP.

In conclusion, a simple technology in the concepts also articulated in the effects on the finished product, which fully reflects the values of the tradition and art of this product, combined with the typicality of the product obtained.

The guarantee of traceability of any form of Provolone Valpadana DOP is obtained through the use of a single company code, numerical and/or alphanumeric, for the identification of the same forms for consumption.