How Provolone Valpadana DOP is made

Home » Provolone Valpadana DOP cheese making

The stages of the production of Provolone Valpadana DOP, between tradition and technology

Production technique

The technology for processing milk intended for the production of Provolone Valpadana DOP cheese is the classic “pasta filata” process, based on physical, chemical and bacteriological criteria and is developed in some essential phases:

The stages of processing

1

Preparing milk in the boiler

Whole cow's milk, with natural acidity and selected in accordance with the provisions of the specification, in terms of geographical origin and diet of the dairy cows, collected within 60 hours of the first milking, can be heat treated up to pasteurisation temperature if it is intended to produce Provolone Valpadana DOP Sweet and to the Spicy type up to 6 kg in weight; while, for the Spicy type over 6 kg, the milk can be, at most, thermised.

2

Addition of lactic ferments and rennet

The lactic ferment culture used in the process is made up of natural whey starter, that is, the microbial culture naturally selected in that given dairy in the whey residue from the cheesemaking process of the previous day. Clearly, whey starter is one of the cornerstones of the cheesemaking process of Provolone Valpadana DOP, as it will be the appropriate bacterial load that will create the conditions for the other phases to follow one another in an optimal way.

Before talking about milk coagulation, it is important to talk about rennet and its types, which then characterize cheese. Rennet (or rennet) is the enzyme complex that modifies the casein in milk, causing the milk to coagulate. There are different types of rennet used in the dairy industry, but two types are authorized for the production of Provolone Valpadana DOP cheese:

- liquid calf rennet (extracted from the calf's abomasum), containing essentially two enzymes (chymosin and pepsin);

- lamb and/or kid rennet in paste formulation (lamb and/or kid abomasums, ground and mixed with salt) containing various enzymes such as chymosin, pepsin, lipase and the complex zymase (entire enzymatic set) of the fourth stomach of sheep and goats, still only partially known today

3

Coagulation

Conceptually, the coagulation of milk (in the production of Provolone Valpadana DOP it occurs at a temperature of around 36-39°C) is the change in physical state of the milk (from liquid to gel), obtained thanks to the action of rennet on the casein dispersed in the milk.

In practice, the casein micelles, instead of "floating" in the milk, after the action of the rennet join together to form a three-dimensional network that incorporates the fat, a part of the whey and the lactic ferments, thus forming a gelatine (dicalcium paracaseinate) commonly called curd.

Ultimately, the liquid calf rennet will give rise to a curd suitable for the production of Provolone Valpadana DOP Dolce, while the lamb and/or kid rennet paste will give rise to a curd suitable for the production of Provolone Valpadana DOP Piccante, as the lipases, together with the complex enzymatic system present, will favor the onset of those complex aromas which, together with the trigeminal sensations, characterize the uniqueness and preciousness of this cheese.

4

Fermentation and cutting of the dough

After processing the milk in the boiler, the curd is left to rest on suitable surfaces, so that it can ferment and acidify to the right point and create the ideal conditions for spinning the dough. This fermentation is nothing more than the continuation of the process started with the addition of the whey starter to the milk and, therefore, to the correct microbial development during the processing and maturation phases of the dough, today, however, this phase is monitored with special equipment. In the past, to see if the dough was ready to be spun, one proceeded by trial and error, immersing a piece of dough in boiling water, to check if it stretched properly, otherwise one waited a little longer and then tried again. From this practice, the names prova, provatura, provola, provolone. Once the point of the right maturation has been reached, the dough is cut and cooled to stop the fermentation and, subsequently, spun.

5

Spinning

This technological practice takes its name from wool spinning, in the sense that the cheese paste is ripe when it is heated and, by pulling it, it stretches to form very long threads.

Just think that just 10 grams of pasta can be stretched up to a meter if you want.

There spinning It occurs in water at high temperatures and, for centuries (incognito), it performed the function of pasteurization ante litteram, that is, before the founder of modern microbiology, Prof. Louis Pasteur (1822-1895), made his discoveries.

In practice the structure of the pasta from grainy and discontinuous becomes fibrous, continuous and plastic. Currently the spinning process can be done, artisanally by hand or, more commonly, using continuous spinning machines capable of ensuring a process respectful of the loyal and constant uses handed down by tradition.

7

Salting

Once the cooling and hardening process is complete, the cheeses move on to the salting phase in brine, where they remain for a few hours up to thirty days, depending on their shape and weight.

During salting, the osmosis process (exchange between miscible liquids) occurs, which favors the entry of salt and the exit of whey.

Once salting is complete, the forms are dried and prepared to enter the maturing warehouses.

8

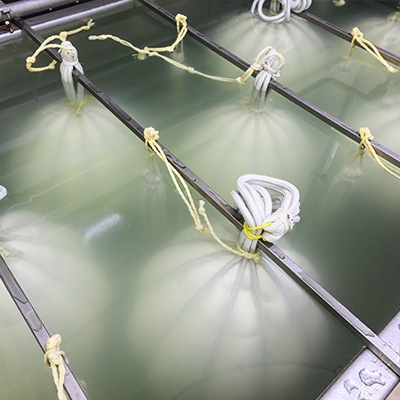

Binding

The preparation phase for maturing involves tying with ropes suitable for contact with food, according to a technique that is as traditional as it is practical and efficient. The type of tying with the “mother ropes” is the cheesemaker’s extra touch. In fact, the niches for the passage of the support ropes are always planned in relation to the shape and weight.

The forms, appropriately tied and possibly smoked, are treated on the surface according to the indications of the current legislation, in order to preserve them from attacks by mould and mites. Before being placed in the warehouse, for the expected maturation period, the rosette is affixed, the brand which identifies only DOP cheese. At the end of the maturing process, the forms will then be labelled and paraffinized to be sent for distribution.

9

Seasoning

Right in the warehouses, thanks to the physical, chemical and microbiological processes of maturation period, we leave the forms wrapped in their fascinating complexity, remembering only that it is the seasoning that releases all the natural sensorial potential of Provolone Valpadana DOP.

In conclusion, a technology that is simple in its concepts but complex in its effects on the finished product, which fully reflect the values of tradition and the art of cheesemaking, together with the typicality of the product obtained.

The traceability guarantee of each form of Provolone Valpadana DOP is obtained through the application of a unique company code, numeric and/or alphanumeric, to identify the same forms until consumption.